A floating head heat exchanger is a type of heat exchanger that has gained prominence across industries for its remarkable flexibility and efficiency. Given its unique design and operation, the floating head heat exchanger is a highly dynamic device that handles various thermal processes, especially those involving wide temperature ranges and high-pressure differentials.

What is a Floating Head Heat Exchanger?

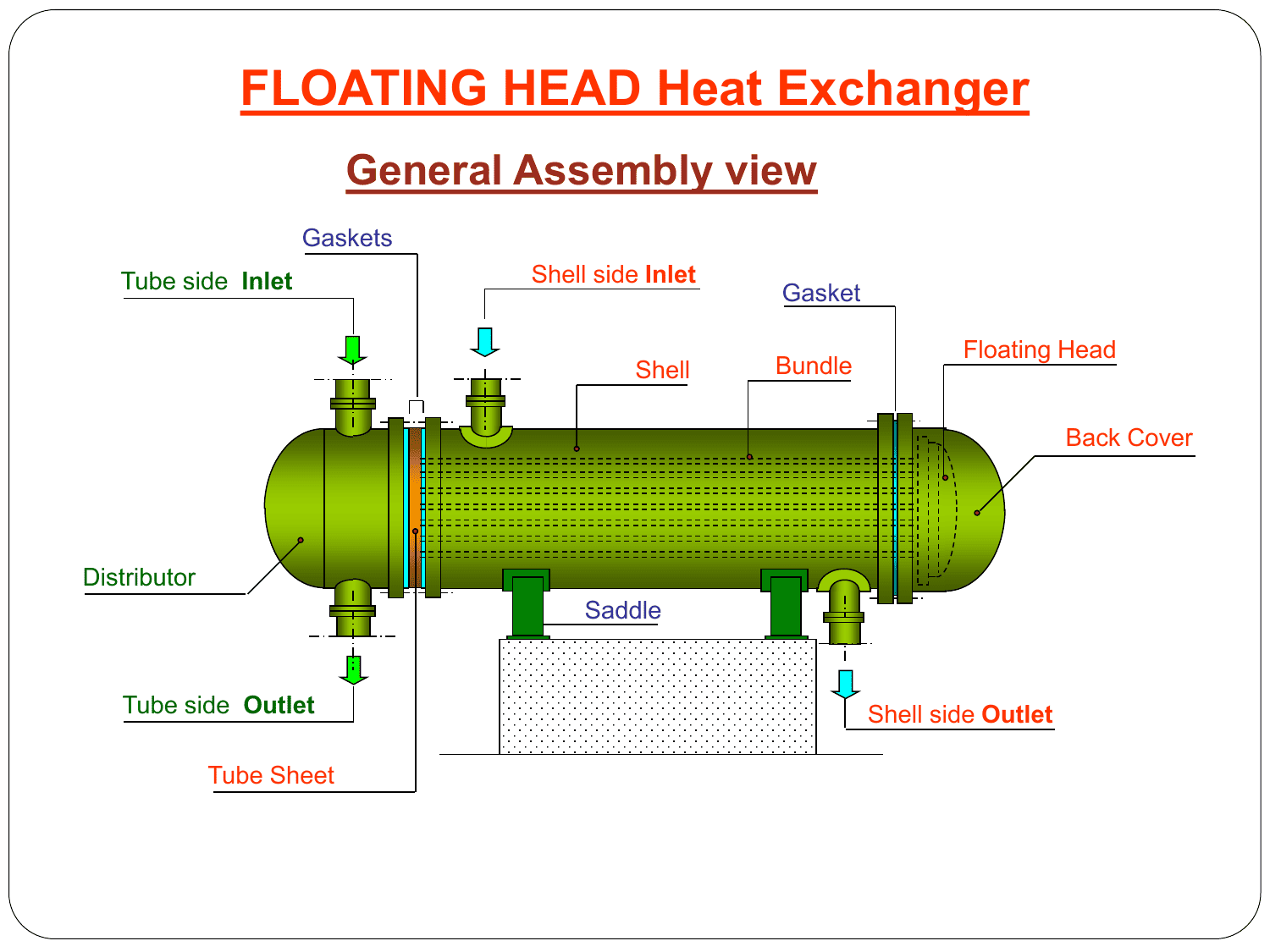

A Floating Head Heat Exchanger is a tube heat exchanger where the tube sheet and shell are designed to allow independent movement. The float heat exchanger facilitates heat transfer from one medium to another without allowing the two media to mix. This process is crucial across many industries and applications, including power generation, chemical processing, air conditioning, refrigeration, and automotive engineering.

In a typical shell and tube heat exchanger, the tubes are fixed at both ends to the tube sheets, which are rigidly connected to the shell. However, in a floating head design, one tube sheet (usually the front-end tube sheet) can move or float within the shell.

The floating head design offers several advantages. One of the main benefits is that it allows for differential thermal expansion between the tubes and the shell. When a heat exchanger operates, the tubes and shell are subjected to different temperatures, causing them to expand or contract at different rates. If the tube sheets were rigidly fixed to the shell, this differential expansion could lead to excessive stresses and potential damage. Allowing the front-end tube sheet to float will enable it to move freely in response to thermal expansion, reducing the risk of mechanical failures.

Another advantage of the floating head design is that it simplifies the heat exchanger’s maintenance and cleaning. Since the front-end tube sheet can be moved away from the shell, it provides more accessible access to the tubes for inspection, cleaning, or replacement. This feature is handy when processed fluids may cause fouling or deposit formation on the tube surfaces, requiring periodic maintenance.

Heat exchangers provide a kind of system that permits the transfer of heat between two or more fluids. In these devices, the fluids are generally separated by a wall to prevent them from mixing. The ‘Floating head’ type of heat exchanger is one of the most commonly used heat exchangers. It is a ‘shell and tube’ heat exchanger that includes parts like the shell, shell-side and tube-side nozzles, tubes, channels of tube-sides, tube sheets, baffles, channel covers, and pass divider.

Design of Floating Head Heat Exchangers

- Structure

The floating head heat exchanger is so named due to the “floating” tube bundle design. This design comprises a cylindrical shell, a tube bundle, and two heat exchanger heads. The “floating” tube bundle is not fixed at both ends. Instead, one end, typically called the “tube sheet,” is stationary and attached to the shell, while the other is free to “float.”

- Tube Bundle and Floating Head

The tube bundle is the heart of this design, containing numerous small tubes that provide a significant surface area for heat transfer. Fluid flowing inside these tubes transfers heat to another fluid flowing outside the tubes but inside the shell. The floating head permits axial movement of the tubes, which enables the heat exchanger to handle significant thermal expansion or contraction that would otherwise potentially damage the device.

- Baffles

In addition to the tube bundle, baffles (plate-like components) are placed inside the shell. These serve the dual purpose of supporting the tubes and directing the flow of the shell-side fluid across the tube bundle, enhancing turbulence and heat transfer efficiency.

IV. Operation of Floating Head Heat Exchangers

The operation of floating head heat exchangers relies on the principle of heat conduction and convection. The hot fluid (one with a higher temperature) enters the heat exchanger and flows through the tubes. The tube walls absorb the heat, transferring it to the colder fluid flowing on the shell side. The floating head design allows the tubes to expand and contract with temperature changes, ensuring durability and reliability even under high thermal stress conditions.

Main Benefits of Floating Head Heat Exchangers

- Accommodates Thermal Expansion

The main advantage of a floating head heat exchanger is its ability to accommodate thermal expansion and contraction. This is a significant design improvement over fixed heat exchangers, reducing the risk of thermal stress and subsequent mechanical failure.

- High-Pressure Operations

Its robust design makes the floating head heat exchanger withstand high-pressure differentials, making it suitable for high-pressure operations.

- Efficient Cleaning and Maintenance

Floating head heat exchangers allow easy dismantling for cleaning, maintenance, and inspection. In addition, the floating tube bundle can be pulled from the shell, facilitating comprehensive cleaning and minimizing downtime.

Applications of Floating Head Heat Exchangers

- Chemical Industry

In the chemical industry, these heat exchangers are extensively used in high-pressure and high-temperature applications such as distillation columns, where thermal stress is a significant concern.

- Oil and Gas Industry

The oil and gas industry typically uses them for cooling and condensing due to their ability to handle significant temperature changes and high-pressure differentials.

- Power Generation

In power plants, they cool down hot steam after it has been used to turn the turbine, recycling the steam back into the water for reheating and turning it back into steam.

Floating Head Heat Exchanger Advantages

- Flexibility in Thermal Expansion: Floating head heat exchangers are designed to handle the differences in thermal expansion between the shell and tube materials. This makes them ideal for applications with vast temperature differences or cyclic processes.

- Easy Maintenance: Floating head heat exchangers often have removable tube bundles, making them easier to clean and maintain than other heat exchangers.

- High Efficiency: Due to their design, these heat exchangers typically offer high heat transfer efficiency, mainly when used with fluids with a significant temperature difference.

- Versatility: They can handle multiple fluids and different heat transfer conditions. They can be used with both liquids and gases.

- High-Pressure Capability: Because of their robust construction, they are well suited to withstand high pressures, especially on the shell side.

- Adaptability to Unequal Temperatures: Floating head heat exchangers can accommodate unequal temperatures between the shell and tube sides, reducing the risk of thermal stress and damage.

- Prevents Leakage: The design of the floating head heat exchanger can help prevent tube-side fluid leakage into the shell-side fluid and the atmosphere.

- Durability: They are designed for long-term, heavy-duty usage. The ability to replace individual tubes contributes to their overall longevity.

- High Surface Area: Floating head heat exchangers have a high surface area to volume ratio, which makes them ideal for applications where space is a consideration.

- Reduced Risk of Thermal Shock: The floating head design can better tolerate rapid temperature changes, reducing the risk of thermal shock damage compared to fixed head designs.

The system design of the floating head heat exchanger resolves several issues related to thermal gradients.

Types of floating head heat exchangers

The floating head heat exchangers are classified into four types based on their design differences. These are an outside-packed lantern ring, an outside-packed stuffing box, a pull-through, and a split ring.

Glance through the details of each of these ‘floating head’ types of heat exchangers:

Floating Head Heat Exchanger Outside-Packed Lantern Ring

This heat exchanger was initially popularly used because of its removable construction system. However, it has a high tendency of leakage due to the lack of a positive seal. Such limitations make it unsuitable for handling hazardous fluids or high pressure. In addition, the outside-packed lantern ring type has only two tubes fitted in it.

Floating Head Heat Exchanger Outside-Packed Stuffing Box

Like the above type, the outside-packed stuffing box has no positive seal, making it vulnerable to leakage. For this reason, it faces the same problems as the outside-packed lantern ring design. However, four tubes in the stuffing-box type of heat exchanger enhance the heat transference speed from one medium to another.

Floating Head Heat Exchanger Pull-Through Bundle

One tube sheet in this heat exchanger is relatively small, allowing it to be pulled easily across the shell. Similarly, its gasket-fitted bonnet can be drawn. This makes the insides of the shell easily accessible for checking, cleaning, and repairing. The downside of this design is that it accommodates fewer tubes compared to other designs. This results in less space for the bolt circle and bonnet flange.

Floating Head Heat Exchanger Split-Ring

A split-ring design overcomes most of the issues posed by the pull-through bundle. In this type of heat exchanger, the floating head’s bonnet is fastened to a split backing used in place of the tube sheet. This arrangement creates sufficient space for the tubes, which couldn’t be held in a pull-through design. Further, the split-ring design also harbors a ‘pull through’ attribute like the heat exchanger system’s pull-through type.

The last two heat exchangers cause lesser leakage than the first two types.

Floating head heat exchanger hydro test procedure video:

Floating head heat exchanger maintenance procedure video:

Conclusion

Floating head heat exchangers are essential in many industries, offering valuable advantages in efficiency, durability, and maintainability. Understanding their design, operation, and applications helps optimize their performance and harness their full potential. Despite the initial higher investment cost than other heat exchangers, their reliability, longevity, and low maintenance requirements often make floating head heat exchangers a highly cost-effective choice over the long term.

- Facebook Ads to Get Followers! - December 27, 2024

- ClickUp vs. Slack - December 20, 2024

- Mastering E-Commerce Analytics: A Blueprint for Success