Concrete is a versatile and durable building material that can be used in a variety of applications, both indoors and outdoors. It is made up of cement, sand, gravel, and water. While gravel – or aggregate – is an essential component of concrete, it can be replaced with other materials to create a different type of concrete. Unlike traditional concrete, this concrete form is called mortar concrete and can be used in various situations.

Concrete is a beautiful material for any construction project. It binds the components to combine and form a firm wall surface that can stay longer in its shape. However, such concrete does not work best for a smooth and clear surface since sandstone or gravel is present.

If you have noticed in old areas that people used to have their sidewalks rocky and old-school-looking, that can be changed, and you don’t want your sidewalks like them. However, the only concern that might be bothersome is how this can be achieved. For example, you can avoid having this kind of curvy sandstone shape.

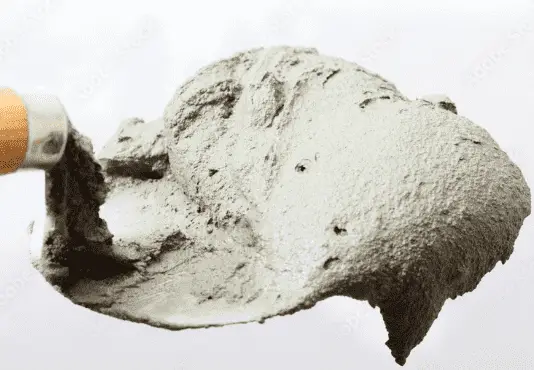

Concrete without rocks:

Can You Make Concrete Without Gravel?

Yes, concrete without rocks or coarse gravel is called mortar concrete. Mortar concrete with a fine-grained appearance is made from Portland cement, sand, and fine aggregate. Famous mortar concrete brands that sell mortar mixes in the US are Sakrete, Quickrete, and Sika.

One of the terms used to explain concrete, which does not contain gravel or rocks, is “mortar concrete.” Several ingredients make it look smoother and plainer when applied. Portland cement, plus fine aggregate and sand, provide a completely smooth look. Once used and let stay set, it will appear as a smooth surface for your sidewalk or any surface you want to work on.

See on the image left, “mortar concrete.”

Mortar concrete is made from Portland cement, sand, and a fine aggregate such as crushed stone or ash. As the name implies, mortar concrete has a finer consistency than regular concrete since it does not contain coarse-grained gravel particles. It has a smoother appearance than traditional concrete and often looks like a paste when mixed with water. Mortar concrete can also be more robust because its cement-to-aggregate ratio is higher than conventional mixes (2:1 for mortar vs. 1:2 for regular concrete).

While mortar concrete doesn’t contain large pieces of aggregate or rocks like traditional mixes, it still requires careful mixing to ensure the correct proportion of Portland cement to sand to aggregates is used. This helps ensure that the desired strength of the finished product will be achieved when cured. Numerous brands make pre-mixed mortar mixes, such as Sakrete, Quickrete, and Sika, that help simplify this process by providing an easy-to-use product with predetermined ratios already included.

Mortar concrete can be used instead of regular concrete when greater strength or improved aesthetics are needed. It can be used for masonry projects like stucco walls or tuckpointing bricks. Additionally, mortar concrete can be an adhesive between two surfaces, such as laying bricks or tiles onto a foundation wall without using traditional grout materials. For outdoor applications like walkways and patios, mortar concrete may also provide more excellent durability due to its increased strength compared to regular mixes containing gravel particles, which may eventually break down due to weathering effects from rainwater runoff or frost action in colder climates.

In conclusion, while most types of traditional concrete require gravel for construction purposes due to its ability to increase strength and stability when properly mixed and cured, there are alternatives available, such as mortar concretes, which replace traditional aggregates with fine-grained materials like crushed stone or ash – giving them improved aesthetic qualities with increased durability and strength when compared to regular mixes containing rock particles. Those looking for specific products designed for these jobs should consider brands like Sakrete, Quickrete, and Sika, which specialize in pre-mixed mortars intended for easier use while maintaining solid properties comparable to those found in more conventional concretes containing gravel particles.

Famous brands in the US that sell mortar concrete mixes are:

- SIKA

- QUIKRETE

- SAKRETE

These are concrete mixes made up of fine aggregate material, so there may be rocks, but you can use other methods to avoid having stones in your concrete material.

Read on to determine which brands sell the best fine aggregate concrete and how you can make your aggregate concrete material.

Here is the following list.

1- Concrete Aggregates

What is aggregate in concrete?

Concrete aggregates are inert granular materials such as sand, gravel, crushed stone slag, recycled concrete, and geosynthetic aggregates. Fine aggregates usually consist of crushed stone or natural sand, with most particles passing through a 3/8-inch sieve. Concrete aggregates provide concrete strength, thermal and elastic properties, dimensional stability, and volume stability.

In this article, the word aggregate is used more often, indicating that the material is mixed with other components to create a new, mixed-up material for the concrete mix.

Concrete aggregates are the sand, cement, rocks, and gravel components that create the new concrete mix. Every combination has various aggregates present in them; some have less, and some get high doses, but it is for sure that every mix has the aggregates present in them.

There are two types of aggregates, two of them are following:

- fine aggregates

- Coarse aggregates.

Fine aggregates

These are delicate components like sand and ground gravel. These textureless materials give the gravel surface a smooth and delicate touch.

These aggregates are almost textureless to the touch and have no visual appeal, so they are what you are looking for in a mix without rocks or large gravel, giving an almost clear visual appearance. On the other hand, crushed concrete, gravel, or rocks are components (aggregates) that can provide an apparent texture when added to concrete. Since they are all present in many concrete, they are all present already.

Here is the concept of what aggregates would be and their ideas. What must they do with that if they are in your concrete material?

To put it simply, aggregates are materials that are being added to or already present in the concrete to enhance the concrete mix’s strength.

The aggregates help increase the strength and durability of the concrete mix. After the final appearance, they also add smoothness and fineness to the concrete material (mix).

Different aggregates work differently, and multiple aggregates can have numerous features—similarly, they are put in other materials according to their features and capabilities.

Many people might wonder about the difference between the concrete add-ups, whether the concrete aggregate with the strength is more appropriate or the other with gravel or stony would be preferable.

So here are some facts that will help you decide. Since many people want a smooth and fine surface for the concrete they have used, fine sand-like concrete (aggregates) will be a perfect choice.

But there is one disadvantage: this fine aggregate concrete offers a lower strength. Because of this quality, this fine aggregate concrete is used for construction areas where less traffic is expected and, most of the time, in areas where there is no way to cross.

Mortar Concrete Mixes

If you want the recommendations for all other concrete mixes with or without the gravel stone in them. This is the right portion of the article to gain precise knowledge about concrete.

The fine aggregates that give the fine and sleek look are known as the “mortar mixes.” So this is the terminology that will help you ask in the market about this product. Since the word fine aggregates does not always suit the shopping way of many people, Having complete knowledge of the desired outcome is better than buying without know-how.

Can you sand down the concrete?

If you do sand finish, you can create concrete-like sand (sand color), known as the sand-textured decorative flatwork option. Placing, finishing, and stamping sand-colored concrete can cost from $5 to $15 per square foot.

Usually, people sand down concrete using sandpaper with grit between 40 and 60. However, various sand finish options can help with this.

The Best Mortar Mixes to make Concrete without Gravel

Mortar mixes are preferable for the instructions of areas like walls and countertops. These mortar mixes are the interior’s major part of the construction, and for you, we have researched mortar mixes on the internet. They find out which mortar mix products are affordable at which rate and what most people have to say about them.

We are confident they will be the best commercial option for your mortar mix project.

Here is the first product:

Sakrete Mortar Mix Type N:

This mortar mix comes in various packaging, but a 40 lb bag arrives at $32.49. Source. Plus, it has fantastic reviews and five stars on Amazon.

Quickrete Mortar Mix:

Quickrete’s 60 lb mortar mix sells for $41 on Amazon and is rated five stars. Source. Quickrete is also a reliable and popular brand, making it a safe choice if you have never worked with mortar concrete.

DIY Fine Aggregate Concrete

You can always try this straightforward construction project at home. Here is the list of the components you will need for this project, and then you will see the details about how you can mix up what product to apply in which quantity.

- Fine sand

- Portland cement

- Aggregates

- Water

- Tools to apply the material (concrete)

- Buckets to mix the mixture

Once you have these components, it’s time to start measuring; here are the basic measurements.

- 1 part of cement

- Two parts of sand

- Four components of fine aggregate.

Take a mixer and add these components to that mixer. Mix them until you get a fine, uniform, grounded powder shape (form). After this, add some water when all the material is thoroughly mixed. Mix with a small quantity of water until you get a perfect consistency.

Adding too much water at once can ruin the material (concrete). Then, add the mixture to the holder; here is one of the best tips to make half the required concrete mix. By doing this, you can get fresh concrete material every time. So precisely, your material is enough in the first round; you won’t need to make the second round, which can save your concrete. Plus, making all the material can affect the concrete since the remaining material in the holder will dry and become useless when applied.

Tip: Help yourself by writing down all the procedures first and then starting the project. This will help you be more organized and efficient. As a result, you will be less likely to forget anything and will end your project more perfectly.

Ask your friends to help you with the construction, so this will never end. Only you all have to clean up the mess of the remaining things and tools.

Conclusion

In conclusion, while you cannot mix mortar and concrete directly due to their differing water contents, it is still possible to make concrete without gravel. To do this, other additions, such as sand or sawdust, can be used in place of the gravel to provide texture and strength. These additives can be mixed with mortar to create a cement-like material suitable for various construction applications.

Furthermore, adding these substances may also help reduce shrinkage and cracking once the mixture has hardened. Of course, it is essential to note that using substitutes for gravel may affect the overall strength of the final product, so it should be done with caution, and appropriate safety measures should be taken when handling the materials. While some drawbacks are associated with making concrete without gravel, it is possible under certain circumstances.