Sand mills are essential in various industries because they allow efficient and uniform dispersion of pigments, dyes, coatings, and other substances in a liquid medium. This is crucial in chemical, ink, and paint manufacturing industries, where the quality and consistency of the final product are critical to its success.

What is a Sand Mill?

A sand mill is a grinding mill that uses tiny beads or balls made of glass, steel, or other materials to grind and disperse pigments, coatings, inks, and other substances. The sand mill operates by agitating the beads and material mixture in a closed chamber, allowing for a homogeneous mixture and reducing fine particle size. Sand mills are commonly used in the chemical, ink, and paint industries, as well as in pharmaceuticals and food production.

A central bar is in a sand mill, which stirs the sand and causes the grinding process. Different sand mills produce other particles; one mill may produce small fine particles. Simultaneously, some have a recapture system that lets the user pass that mixture through the sand mill again to make the particles more exceptional. The design’s working model is simple, i.e., stir the sand rather than create any pressure so that the grinding medium may not get damaged and work properly.

As the name represents, sands can be used as grinding passages, but certain other materials can also be used. The medium depends on the type of document being used. Some companies maintain the same settings involving only one medium, while others may change the medium per the needed single sand mill. Sand Mills can also be used in different manufacturing units, such as paints and related products.

In the case of a mixture, sand mills run the mix and have a fine paste or powder due to processing. This process works in producing paints where the mixture needs to be in high-quality components. The ingredients are left in the sand mill, and the mixture is ready when it passes through it. In addition, the fine grind provided by this equipment allows stable mixes without any blockage and smudge.

Companies offer sand mills on rent or lease based on requirements. This enables the user to try the equipment and decide whether to purchase it. Buying used or revamped equipment from a manufacturer or a third-party source is possible, as a brand-new sand mill can be expensive. The grinding media is available from the sand mill’s manufacturer or supplier. The user or operator must use the best source for given equipment, considering everything, including defile concerns.

Sand Mill Features

- It uses tiny beads or balls made of glass, steel, or other materials to grind and disperse materials.

- Operates by agitating the beads and material mixture within a closed chamber

- Allows for efficient and uniform dispersion of pigments, dyes, coatings, and other substances in a liquid medium

- Can produce fine particle sizes for desired product properties and performance characteristics

- Suitable for use in industries such as chemical, ink, and paint manufacturing, as well as in pharmaceuticals and food production

- Can operate continuously for high-volume production

- Can handle a wide range of materials and viscosities

- Offers high energy efficiency compared to other types of grinding mills

- Easy to use and maintain with minimal downtime

- It can be customized to meet specific process requirements and production needs.

A good and efficient sand mill may have a variety of different features. The first thing that best categorizes a sand mill is its installation. Many companies manufacture sand mills worldwide, but the one that helps with the straightforward structure is considered best. An extensive and bulky sand mill may take good working hours for the installation and extra labor charges. Spare time and money account for the initial loss for a business. The mill and company that claims quick and easy installation is best.

The speed and growth of particular things depend on how efficiently work is done. Therefore, efficiency is a must for any equipment. A Sandmill should function efficiently in the long run. Efficient machinery can work faster and give better results. A company must guarantee the kit’s function in the long term. Buyers should consider the efficiency clause, whether buying directly from the company or supplier.

How does a sand mill work?

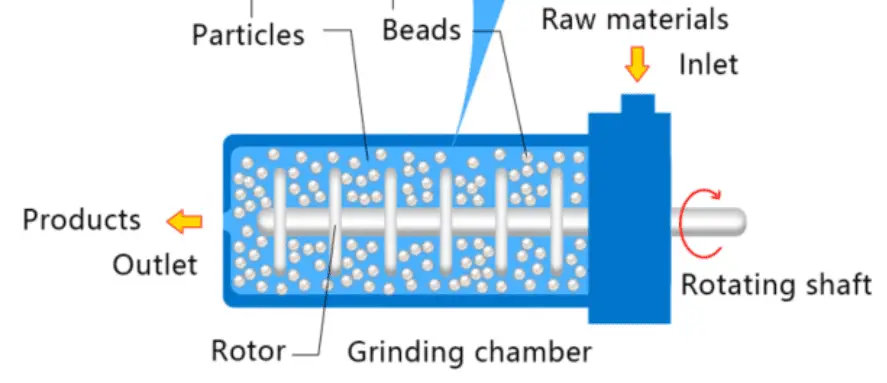

The sand mill works when processing materials are pumped to the milling chamber from the mill’s bottom. The material moves upwards in this process because it is subjected to high shear forces between the grinding media. In the end, the result is fine grinding of the material.

- A sand mill uses tiny beads or balls of glass, steel, or other materials to grind and disperse pigments, coatings, inks, and other substances.

- The material to be ground is placed into the grinding chamber of the sand mill, along with the grinding media (beads).

- The chamber is then sealed, and the grinding media are agitated by a rotating shaft or impeller.

- The agitated beads collide with the material, breaking it into smaller particles and dispersing it in the liquid medium.

- The rotation speed and direction, as well as the size and material of the grinding media, can be adjusted to control the particle size and distribution of the final product.

- The mixture is continuously circulated through the grinding chamber until the desired particle size is achieved.

- Once the grinding is complete, the mixture is discharged from the sand mill for further processing or packaging.

- The sand mill can be cleaned easily between batches by flushing it with a cleaning solution and rinsing it with water.

A sand mill has many different working principles, but the most commonly used is efficiency. The material that has to be processed is pumped from the bottom to the grinding chamber. A shaft fitted with several impeller discs is used to shake the media. As the material moves up, it receives high shear forces between the grinding media, resulting in fine grinding of the given material. The grinder then passes through the screen that separates the media from the process material. The mills are provided with a jacket arrangement to cool the ground material in the grinding chamber. The sand mills have safety parts that enable maximum efficiency in harsh conditions and the risks involved, making sand mills safer to use.

Horizontal sand mill

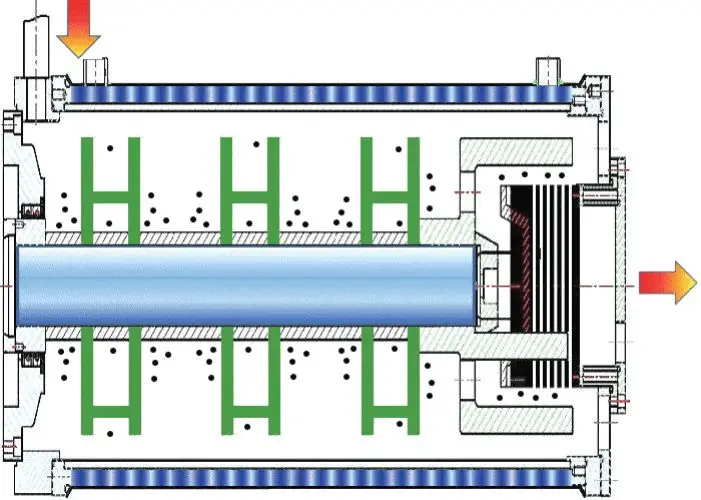

A horizontal sand mill uses tiny beads or balls of glass, steel, or other materials to grind and disperse pigments, coatings, inks, and other substances. As the name suggests, it has a horizontal orientation, with the grinding chamber positioned horizontally.

The material to be ground is introduced into the grinding chamber, along with the grinding media, and agitated by a rotating shaft or impeller. The beads collide with the material, breaking it into smaller particles and dispersing it in the liquid medium. The mixture is continuously circulated through the grinding chamber until the desired particle size is achieved.

Horizontal sand mills are commonly used in the chemical, ink, and paint industries, as well as in pharmaceuticals and food production. They offer several advantages over other grinding mills, including high efficiency, uniform particle size distribution, and easy cleaning and maintenance. They are also suitable for handling highly viscous materials and can be customized to meet specific process and production requirements.

A horizontal sand mill has a flat appearance and is more suitable for grinding products that require high precision and fineness. Although horizontal sand mills have higher manufacturing costs, they work excellently on tight materials and offer high product purity.

Now let us see in the video how horizontal San mill works:

Bead mill

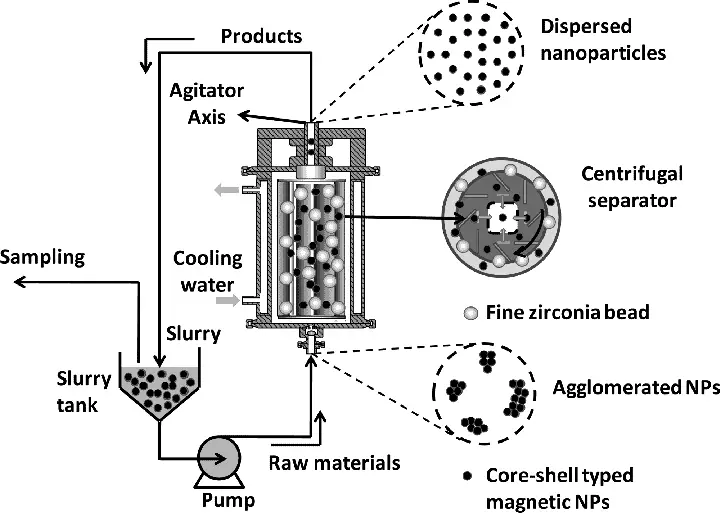

The working principle of a vertical bead mill is based on a process where a shaft fitted with grinding discs rotates within a fixed grinding chamber that has been charged with the chosen grinding beads. Usually, a vertical bead mill is used to grind suspensions and pigment pastes.

Sand Mill vs. Bead Mill

A bead mill is a grinding mill that uses tiny beads or balls made of glass, ceramic, steel, or other materials to grind and disperse pigments, coatings, inks, and other substances. It is also known as a “sand mill” or “pearl mill.”

Bead mills operate by agitating the beads and material mixture within a closed chamber, allowing for a homogeneous mixture and fine particle size reduction. The material to be ground is introduced into the room along with the grinding media (beads), and the mixture is agitated by a rotating shaft or impeller. The beads collide with the material, breaking it into smaller particles and dispersing it in the liquid medium. The rotation speed and direction, as well as the size and material of the grinding media, can be adjusted to control the particle size and distribution of the final product.

Bead mills are commonly used in the chemical, ink, and paint industries, as well as in pharmaceuticals and food production. They offer several advantages over other grinding mills, including high efficiency, uniform particle size distribution, and easy cleaning and maintenance. They are also suitable for handling highly viscous materials and can be customized to meet specific process and production requirements.

Bead and sand mills are grinding mills used to grind and disperse pigments, coatings, inks, and other substances.

Bead mills use tiny beads or balls made of glass, ceramic, steel, or other materials to grind the material. The beads are agitated within a closed chamber, and as they collide with the material, they break it down into smaller particles and disperse them in the liquid medium. Due to the smaller size of the beads, bead mills are generally more efficient than sand mills, which allows for higher levels of energy efficiency. Bead mills are also more effective at handling highly viscous materials.

Sand mills, conversely, use tiny beads or balls made of glass, steel, or other materials to grind the material. The beads are agitated within a closed chamber, and as they collide with the material, they break it down into smaller particles and disperse them in the liquid medium. Due to the larger size of the beads, sand mills are generally more effective than bead mills at handling larger particle sizes. Sand mills are also more effective at achieving a uniform particle size distribution.

Overall, the choice between a bead mill and a sand mill will depend on the process’s specific material and particle size requirements, as well as the desired level of energy efficiency and process flexibility. However, both types of mills offer advantages in uniformity, efficiency, and flexibility and can be customized to meet specific process requirements and production needs.

Advantages of Sand Mill

- Efficient and uniform dispersion of pigments, dyes, coatings, and other substances in a liquid medium

- Can produce fine particle sizes for desired product properties and performance characteristics

- Suitable for use in a wide range of industries, including chemical, ink, and paint manufacturing, as well as in pharmaceuticals and food production

- Can operate continuously for high-volume production

- Offers high energy efficiency compared to other types of grinding mills

- Can handle a wide range of materials and viscosities

- Easy to use and maintain with minimal downtime

- Can be customized to meet specific process requirements and production needs

- Can achieve high levels of consistency and reproducibility in the final product

- It can reduce waste and improve overall process efficiency.

An excellent working sandmill has many advantages. Efficiency is one of the sandhill’s most used and essential terms. An efficient working sand mill may yield high grinding efficiency.

A sand mill has a Wear-Resistant Grinding Chamber. A well-furnished and built grinding chamber is a trusted source for a user. Even at high grinding, the section remains intact.

The Integrated Lifting Device lifts the components and further differentiates them from the mixture, saving the user a lot of time.

Multiple Cooling systems are available in the sand mill, which let the prepared component mixture cool quickly and prepare it for further processing.

A well-built and engineered sand mill consumes less power. Its mechanism is simple and does not require high potential to perform the given process.

Use Of Sand Mill

Sand Mill can be used:

- Chemical industry: for grinding and dispersing pigments, dyes, coatings, and other substances used in the production of chemicals

- Ink industry: for manufacturing printing inks for various printing applications, including offset, flexographic, and gravure printing

- Paint industry: for producing paints and coatings with uniform particle size distribution and consistent color

- Pharmaceutical industry: for grinding and dispersing active ingredients in liquid or semi-solid formulations, as well as for producing nanoparticle-based drug delivery systems

- Food industry: for manufacturing food additives, such as coloring agents and flavorings, with precise particle size and distribution

- Cosmetic industry: for producing cosmetics, such as makeup and skincare products, with uniform texture and particle size

- Textile industry: for dyeing and printing textiles with consistent color and appearance

- Ceramic industry: for grinding and dispersing ceramic materials used in the production of ceramics and glass

- Mineral industry: for processing minerals and ores to achieve the desired particle size and distribution for further processing.

A sand mill’s general and most common use is to reduce particle size. However, the sand mill is also used for different purposes. Some may be used to separate components from mixtures, while others may grind and make fine particles of a particular substance. Sand Mills are most commonly used in the Paint and Chemical Industries. They separate fine particles from chunks and make pigmentation easier.

There are two types of Sand Mills, i.e., Vertical Sand Mills and Horizontal Sand Mills. Both have almost similar working mechanisms. However, they may vary in shape, size, and practical usage.

Sand Mill in the paint industry

Sand Mills in the paint industry obtain the finished paint product after blending. Usually, in the first phase, machines produce a material-mixed slurry by stirring, then dispersing and sanding the materials and various auxiliaries in the next step. Painting is the last step; the output shows stability and high production efficiency. This practice can reduce production costs for users.

- Sand mills are commonly used in the paint industry to grind and disperse pigments, dyes, and other materials used to produce paints and coatings.

- Sand mills can produce uniform particle size distribution, which is essential for achieving consistent color and appearance in the final product.

- Sand mills can handle various highly viscous and abrasive materials, making them suitable for multiple paint formulations.

- Sand mills can produce fine particle sizes, which are crucial for achieving desired product properties such as gloss, durability, and texture.

- Sand mills can be customized to meet specific process requirements, such as temperature control, residence time, and shear rate, which can affect the final product’s properties.

- Sand mills are energy-efficient compared to other grinding mills, making them a cost-effective solution for high-volume production.

- Sand mills can be easily cleaned and maintained with minimal downtime, which is essential for maintaining a hygienic production environment.

- Sand mills can be integrated into automated production lines, providing a highly efficient and reliable solution for paint manufacturing.

- Sand mills can produce various paint formulations, including solvent-based, water-based, and UV-curable paints, making them suitable for use across multiple paint applications.

Overall, sand mills play an essential role in the paint industry by providing a reliable and efficient method for grinding and dispersing pigments, dyes, and other materials, resulting in high-quality and consistent paints and coatings.

Conclusion

In conclusion, sand mills are essential in various industries, including chemical, ink, paint, pharmaceutical, food, cosmetic, textile, ceramic, and mineral processing. They use tiny beads or balls of glass, steel, or other materials to grind and disperse pigments, coatings, inks, and other substances in a liquid medium.

Sand mills offer several advantages, such as efficient and uniform dispersion, fine particle size reduction, high energy efficiency, easy maintenance, and customization. They can also handle a wide range of materials and viscosities, making them suitable for various production processes.

In the paint industry, sand mills are crucial in achieving consistent color, texture, and appearance in paints and coatings. They can produce various paint formulations and are suitable for multiple applications.

Overall, sand mills are important because they provide a reliable and efficient method for grinding and dispersing materials, resulting in high-quality and consistent products. As a result, they continue to be essential tools for modern industrial production processes.

- Facebook Ads to Get Followers! - December 27, 2024

- ClickUp vs. Slack - December 20, 2024

- Mastering E-Commerce Analytics: A Blueprint for Success